Goode Sport

Goode Sport is the leading independant racket sport distributor in the UK

Vőstra 8 300g

NEW!

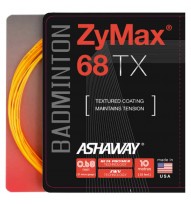

Zymax 68 TX

NEW SURFACE COATING

Powerkill Meta ZX

FOR THE ADVANCED PLAYER

Superlight 11 Hex

SUPERLIGHT FRAME

Latest News

Keep up to date with all things Goode Sport

24th Jul

Success for Ashaway at EUSA

20th Jul

Ashaway Squash Exhibition Match

17th Mar

ADRIAN WALLER SIGNS FOR BLACK KNIGHT

-

Newsletter

We would like to keep you updated with regular updates about our product, news, event and competitions.

Please enter your email below to stay in touch

-

Register Your Product

Enjoy exclusive benefits by registering your product

- 12 months warranty against manufacturing faults

- Subscription to our newsletter

- Exclusive coaching tips, string information and offers on the latest products